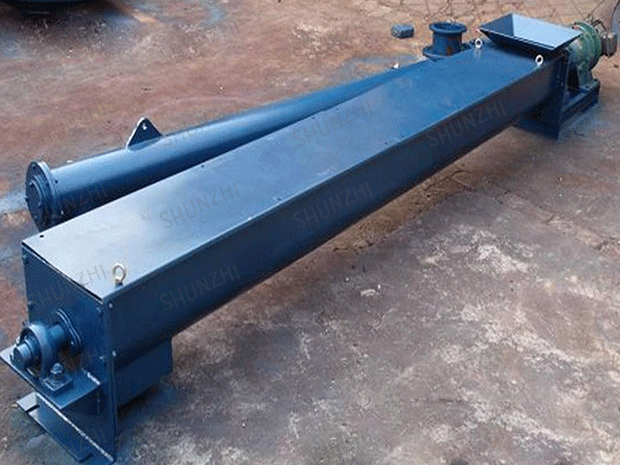

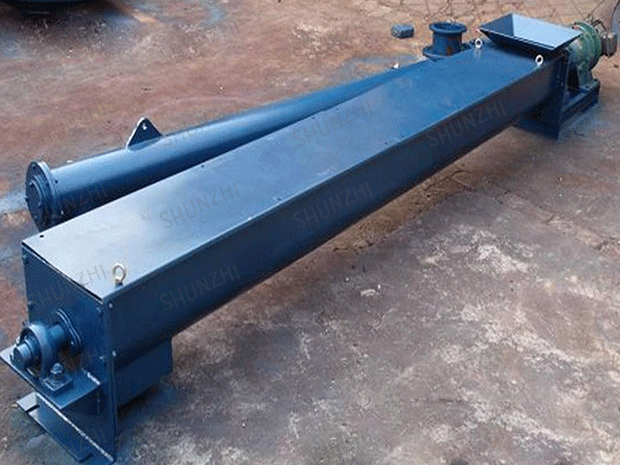

Brand: SHUNZHI

Model: BM1200*4000/BM1400*4000/BM1600*6000/BM1800*8000

Power: 5.5kw/7.5kw/11kw/15kw

Use: Fertilizer coating

Screw conveyor, chicken manure and cow manure organic fertilizer conveyor is a kind of conveying equipment widely used in grain, oil and construction industry. From the perspective of conveying material displacement direction, screw conveyor is divided into horizontal screw conveyor and vertical screw conveyor. There are two types of conveyors, which are mainly used for horizontal conveying and vertical lifting of various powder, granular and small lumps and other loose materials.

The rotating screw blade pushes the material to be conveyed by the screw conveyor, and the force that prevents the material from rotating with the screw conveyor blade is the weight of the material itself and the frictional resistance of the screw conveyor casing to the material. The spiral blade welded on the rotating shaft of the screw conveyor, the surface type of the blade has solid surface type, belt type surface type, blade surface type and other types according to the different conveying materials. The screw shaft of the screw conveyor has a thrust bearing at the end of the material moving direction to give the screw axial reaction force with the material. When the length of the machine is long, an intermediate hanging bearing should be added. The screw conveyor is generally composed of three parts: the conveyor body, the inlet and outlet, and the driving device; the screw blade of the screw conveyor has three forms: solid helical surface, belt helical surface and blade helical surface. Relatively few, it is mainly used for conveying materials with high viscosity and compressibility. This kind of screw suspension type has the functions of stirring and mixing materials at the same time in the process of completing the conveying operation. Compared with other conveying equipment, the screw conveyor has the advantages of small cross-sectional size, good sealing performance, stable and reliable operation, multi-point loading and unloading in the middle, safe operation, and easy maintenance.

The structure is simple, the cross-sectional size is small, the sealing performance is good, the work is reliable, and the manufacturing cost is low. It is convenient for intermediate loading and unloading. During the conveying process, the materials can also be stirred, mixed, heated and cooled. The material flow can be adjusted through the loading and unloading gate. However, it is not suitable to convey materials that are perishable, viscous, easy to agglomerate and bulky. During the conveying process, the material is easily broken, and the screw and the trough are easily worn. The unit power is larger. In use, the sealing of the trough and the proper clearance between the screw and the trough should be maintained.

| Model | Diameter(mm) | Thickless(mm) | Reducer | Capacity(m³/h) |

| Screw Conveyor | 165-273 | 3 | Hardened Gear Reducer | 0-30 |

Overseas marketing outsourcing services for small and medium-sized enterprises.